Epoxy Spray Pipe Lining is one of the primary services offered by Almco Plumbing in San Diego County, California. This method of repairing damaged sewer lines eliminates the need for extensive excavation, reducing the restoration costs typically associated with post-repair landscaping. For several years, we have specialized in this innovative, trenchless pipe repair solution for both residential and commercial properties.

Read on to learn how spray epoxy pipe lining can repair sewer line damage without digging up your yard, driveway or home.

Contents

What is Spray Epoxy Pipe Lining?

Spray Epoxy Pipe Lining is a trenchless method of repairing and protecting damaged sewer and drainage pipes. Instead of digging up and replacing the entire pipe system, this technique involves spraying epoxy resin onto the inside walls of the pipes to form a seamless, durable, corrosion-resistant coating. The epoxy lining seals cracks, stops leaks and prevents further corrosion of the pipes.

This method renovates underground sewer and drainage systems without disruptive excavation. It works on a variety of pipe materials, including cast iron, clay and PVC, and is effective in both residential and commercial applications. The epoxy lining holds the pipe in place, making it last longer without having to completely replace it. This technology is superior for repairing leaks, root intrusion and corrosion—all common problems in sewer and drainage systems.

When to Use Spray Epoxy Pipe Lining?

Spray epoxy pipe lining is a practical alternative to traditional repair methods that can be expensive or invasive. Here are some reasons you should consider spray epoxy lining.

- Water Won’t Drain. Frequent standing water in your sink, bathtub or toilet indicates that your pipes are damaged or clogged. These clogs are often caused by cracks, misaligned joints, or irregularities in the interior walls that trap debris. Epoxy lining solves these problems by restoring a smooth pipe surface and sealing gaps.

- No Excavation. If the area above the damaged pipes is paved or landscaped, epoxy lining eliminates the need for large excavations, preserving the landscape while repairing the pipes.

- Preventive Sewer Inspection Problems. When inspections show early signs of deterioration, such as thinning pipe walls or small gaps in joints, epoxy application can prevent further deterioration and extend the life of the system.

- Structural Damage. Where settlement or external loads (such as active road traffic) have caused small displacements or cracks in sewer pipes, epoxy lining can repair and strengthen the pipes without replacing them.

Spray epoxy pipe lining is especially beneficial when sewer and drainage problems occur in hard-to-reach areas. This solution can fix existing problems and prevent potential future damage, making it an excellent choice for long-term maintenance.

Epoxy Lining Process Step-by-Step

Applying epoxy requires specialized equipment and skills that professional teams like Almco Plumbing have. We offer trenchless sewer repair services, including epoxy pipe lining, near you in San Diego, CA.

The following step-by-step description of the technology will give property owners an overview of the process.

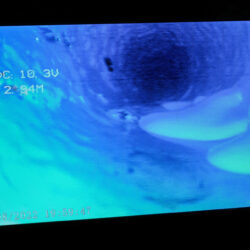

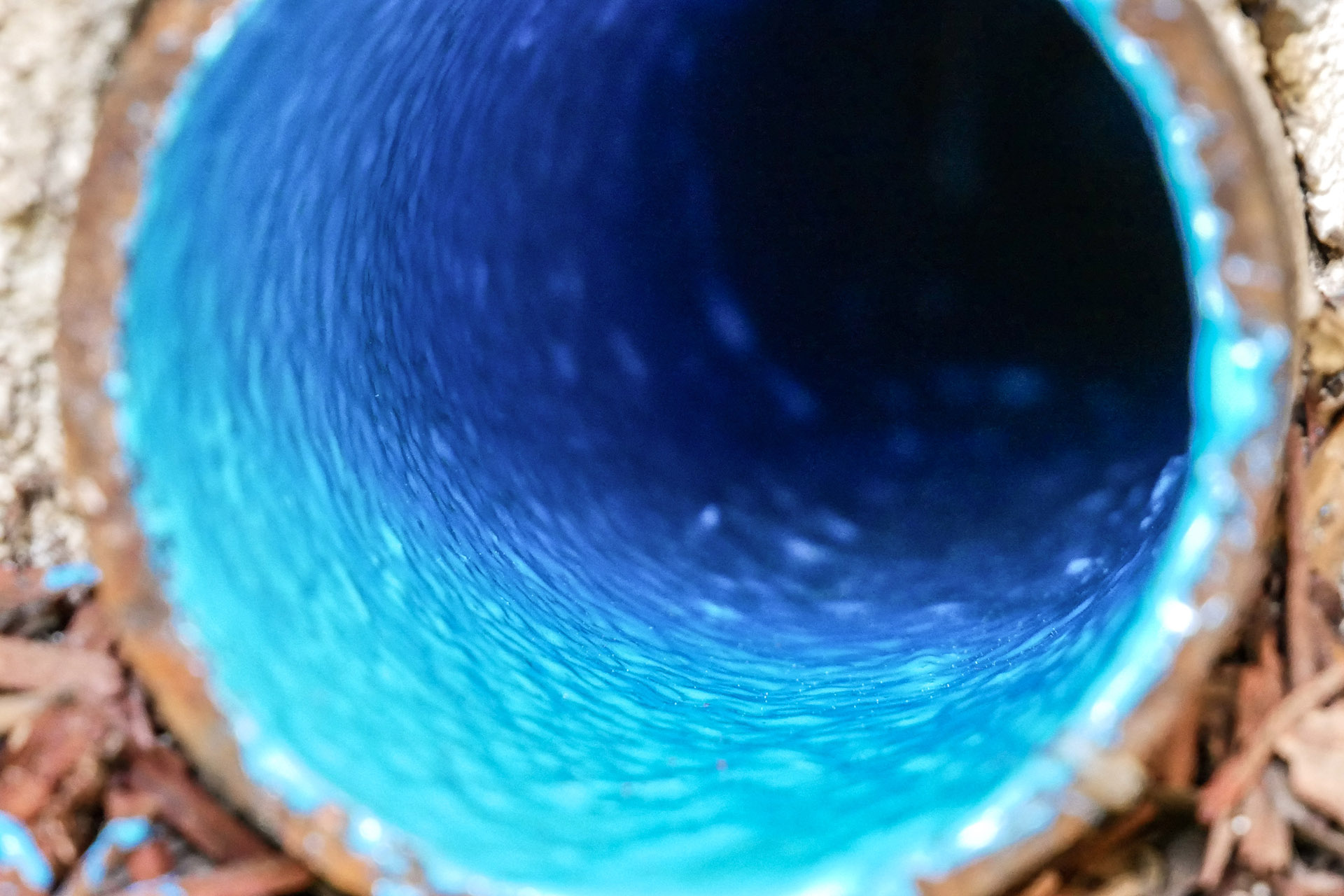

The first step is to assess the condition of the inside walls of the pipe with a CCTV camera. This allows the plumber to find any hidden damage to the sewer lines, and to assess the extent and options for repairing these problems.

This step prepares the inside of the pipes for epoxy coating by thoroughly cleaning them. The professionals at Almco Plumbing in San Diego recommend cleaning the sewer lines with a carbide chain. This is an easy and risk-free way to remove clogs from the inside of worn sewer pipes and restore them to their original size.

The immediate process of epoxy lining is to coat the inside of the old pipe, which has been cleaned of corrosion and other debris, with layers of epoxy resin. The coating is applied mechanically or, very rarely, by hand. Depending on the condition of the original pipe, 2–3 layers of epoxy may be applied. But even with many layers, the total thickness of the coating does not exceed about one-tenth of a ⅜”.

This is the final part of the process where the technician uses a camera to carefully inspect the quality of the applied coating and all the pipe branches. Only when our technician is satisfied that everything is working as it should, without hitches or problems, and the flow capacity of the system has been restored, is the job considered complete.

The epoxy coating cures completely in a few hours, so the customer can usually use their sewer the same day.

When working in older San Diego homes, the Almco team most often uses a carbide-chain picote machine to not only clean pipes, but also to:

- cut tree roots;

- polish the inside of the pipe in preparation for lining;

- grind and remove offsets in pipes or joints between pipes where dirt can get stuck and cause blockages;

- remove mineral deposits from hard water or other scale buildup in pipes.