Secrets of Installing a Tankless Gas Boiler: A Real Case from Almco

A tankless water heater (also known as a condensing boiler) is one of the most efficient and environmentally friendly solutions for residential heating. These units offer reduced energy consumption and lower emissions compared to traditional systems. In this case study, we share Almco Plumbing’s hands-on experience replacing a conventional tank-style gas water heater with a modern tankless boiler—and highlight the advantages of this technology for private homes.

Contents

Technologies & Services

Client’s Problem

Our client contacted Almco Plumbing to replace a 75-gallon gas water heater with a high-efficiency tankless unit.

Removing the Old Heater & Preparing for Installation

- The process began by shutting off the gas and water supply valves to ensure safe removal.

- All water and gas connections were detached, and the remaining water in the tank was drained.

- After removing the tank from its wall brackets, we installed a new mounting bracket in the same location using heavy-duty anchors.

- Once unpacked, the new condensing boiler was prepared for installation.

- Transport plugs were removed, and new bronze fittings and ball shut-off valves were installed using silicone-based plumbing sealant. This prepped the boiler for secure wall mounting.

Gallery: Removing of the Old Water Heater

Installing the Tankless Gas Boiler in a Residential Setting

Water supply and drain piping were assembled on-site using copper pipes cut to size, with elbows, adapters, and fittings for both hot and cold water lines. All joints were soldered to ensure long-term durability.

Two additional connections were needed for the tankless unit:

- Vent pipe for exhausting combustion gases

- Condensate drain for disposing of condensation byproduct

The vent pipe, made of PVC, was routed along the ceiling and secured with metal hangers and clamps. One end connected directly to the boiler; the other exited through an exterior wall, passing through a damper gasket. A diamond-core bit and cordless drill were used to bore the necessary opening in the concrete.

Routing the condensate line presented more of a challenge. A 36-inch horizontal hole had to be drilled through a false column while maintaining a consistent quarter-inch per foot downward slope. Using extension bits and a concrete core drill, the task was completed successfully. After all connections were made, both the gas and water systems were pressure tested—no leaks were found.

Gallery: Example of Installing the Tankless Gas Boiler

Advantages of Tankless (Condensing) Water Heaters

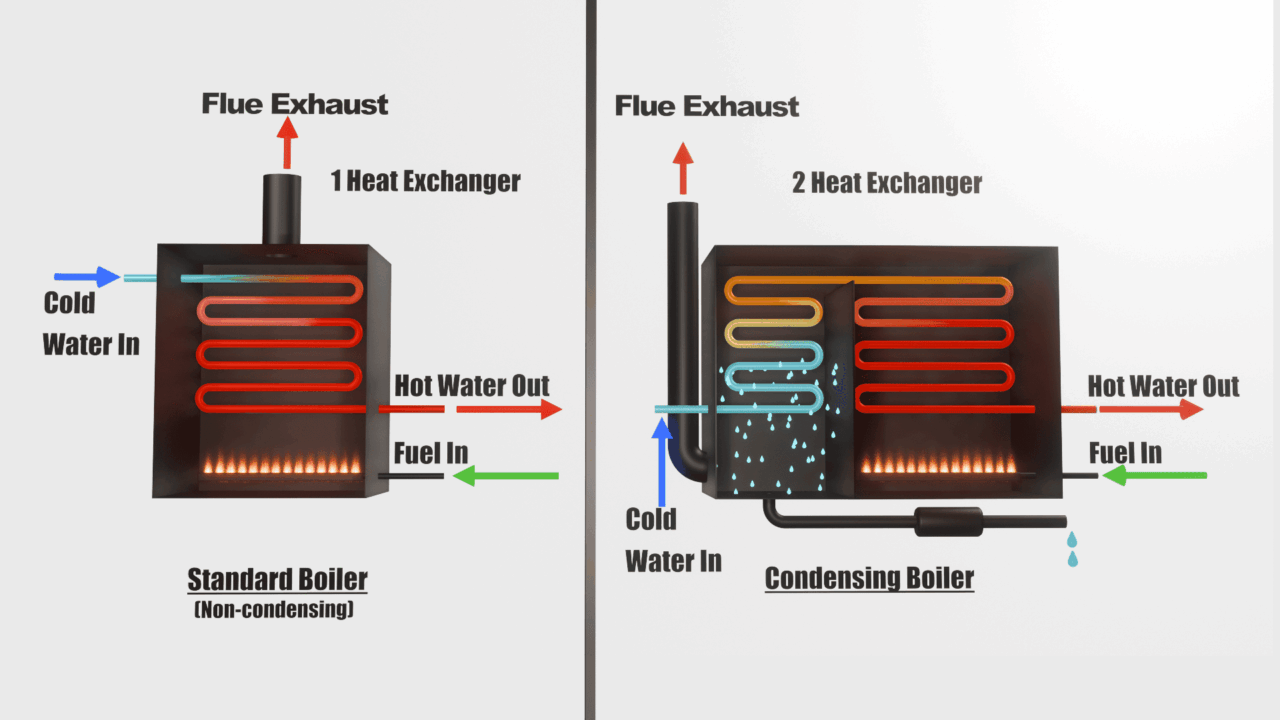

Unlike traditional gas water heaters, condensing (tankless) boilers reuse heat energy from exhaust gases by capturing condensation. When incoming water is cold, it causes vapor in the exhaust to condense—releasing heat, which is then reused to warm the water.

These systems can achieve efficiency ratings as high as 98–99%, meaning almost all energy from gas combustion is used for heating. As a result:

- Fuel is used more efficiently

- Carbon dioxide (CO2) and nitrogen oxide (NOX) emissions are significantly reduced

- Operational costs are lower, making the system ideal for homeowners focused on long-term savings and environmental responsibility

Tankless vs. Tank Water Heaters: Cost, Lifespan, and Maintenance

At first glance, tankless water heaters are more expensive than traditional units. However, conventional systems continuously maintain water temperatures between 130–150 °F, even when no hot water is being used—leading to significant energy waste.

Tankless models heat water only on demand, offering immediate savings. Though initial equipment and installation costs are higher, they typically pay for themselves within a few years thanks to reduced gas bills. Over a 30-year span, tankless units offer superior performance and lower total ownership cost.

Lifespan

- Tank Heaters: 10–15 years average, with a 6-year warranty

- Tankless Heaters: 30-year average lifespan, with a 15-year heat exchanger warranty

Maintenance

- Tank Heaters: Should be flushed annually to reduce sediment buildup

- Tankless Heaters: Require regular descaling to remove calcium from internal piping

Neglecting descaling for more than 2–3 years can severely restrict water flow and damage the heating element. At Almco Plumbing, we do not service neglected units, as descaling in such cases may cause leaks due to corrosion.

A whole-house filtration system can significantly extend the life of a tankless heater, as well as all other plumbing fixtures.

DIY maintenance is possible using a $350 flushing kit and a $30–$50 alkaline solution, making upkeep affordable for homeowners.

Despite the higher upfront investment, condensing tankless water heaters offer:

- Significant fuel savings

- Durability and low maintenance

- Eco-friendly performance

- Ideal compatibility with radiant floor heating and other efficient systems

For private homes focused on energy efficiency and sustainability, this technology is a smart and future-proof solution. In commercial and industrial settings, condensing boilers can drastically cut operational costs while enhancing environmental compliance.