How to Avoid Costly Sewer Main Line Repair with CIPP Inversion: Case of Almco Plumbing

CIPP inversion is one of the most advanced trenchless technologies for repairing sewer systems, and it continues to prove its effectiveness and cost-efficiency in real-world applications. Traditional sewer repair methods are time-consuming and, once all associated costs are factored in, considerably more expensive. In this case study, the specialists at Almco Plumbing share their successful experience using CIPP inversion technology to restore the main sewer line of a private home in San Diego.

Contents

Technologies & Services

Customer Complaint: Frequent Blockages & Sewer Odors

The residents of a private home in San Diego were dealing with persistent sewer backups and unpleasant odors spreading across their property.

A site inspection revealed that the problem was caused by severe wear and deterioration of the underground sewer pipe. The pipe’s reduced internal diameter significantly restricted wastewater flow between the house and the municipal sewer system.

The primary goal of the project was not only to restore the structural integrity of the pipeline on a tight budget but also to eliminate the risk of future blockages.

Almco Plumbing’s Solution & Preparatory Work

After reviewing the layout of the sewer system on the property and within the home, the Almco Plumbing team began the preparatory phase. First, a small section of lawn was carefully removed, and a narrow trench was dug by hand to complete several key tasks:

- Visually assess the overall condition of the sewer pipe

- Choose the most appropriate repair method

- Install new access cleanouts for future system maintenance

The inspection revealed that the existing cast iron main line was heavily corroded and structurally compromised—making spray or brush epoxy lining ineffective. Given the extent of the damage, the team at Almco Plumbing made the only viable decision: to proceed with CIPP inversion.

This method involves installing an epoxy-saturated liner inside the damaged section of pipe. The liner seals all corrosion holes and voids, eliminating leaks and restoring the pipe to a serviceable condition with a projected lifespan of at least 50 years. A synthetic felt liner impregnated with epoxy resin was inserted into the pipe using the inversion method. Just three hours after installation, the home had a fully restored, high-quality sewer line.

CIPP Inversion Process: Step-by-Step Overview

The process of repairing pipes with CIPP inversion technology is described below.

To remove scale, grease buildup, and obstructions, the crew used a high-pressure hydro-jetting system with precision nozzles. Water was delivered at a pressure of 4,000–4,500 psi and a flow rate of 17 gallons per minute, ensuring a thorough cleaning of the pipe interior.

Following that, a mechanical chain cutter was used to clear away residual calcium deposits and corroded areas. To create a perfectly smooth surface for the liner, the pipe was further polished with an abrasive attachment—removing any remaining burrs, rough edges, or fine debris.

A CCTV camera inspection was then conducted to confirm the cleaning results. The pipe was flushed once more with pressurized water and dried using forced air.

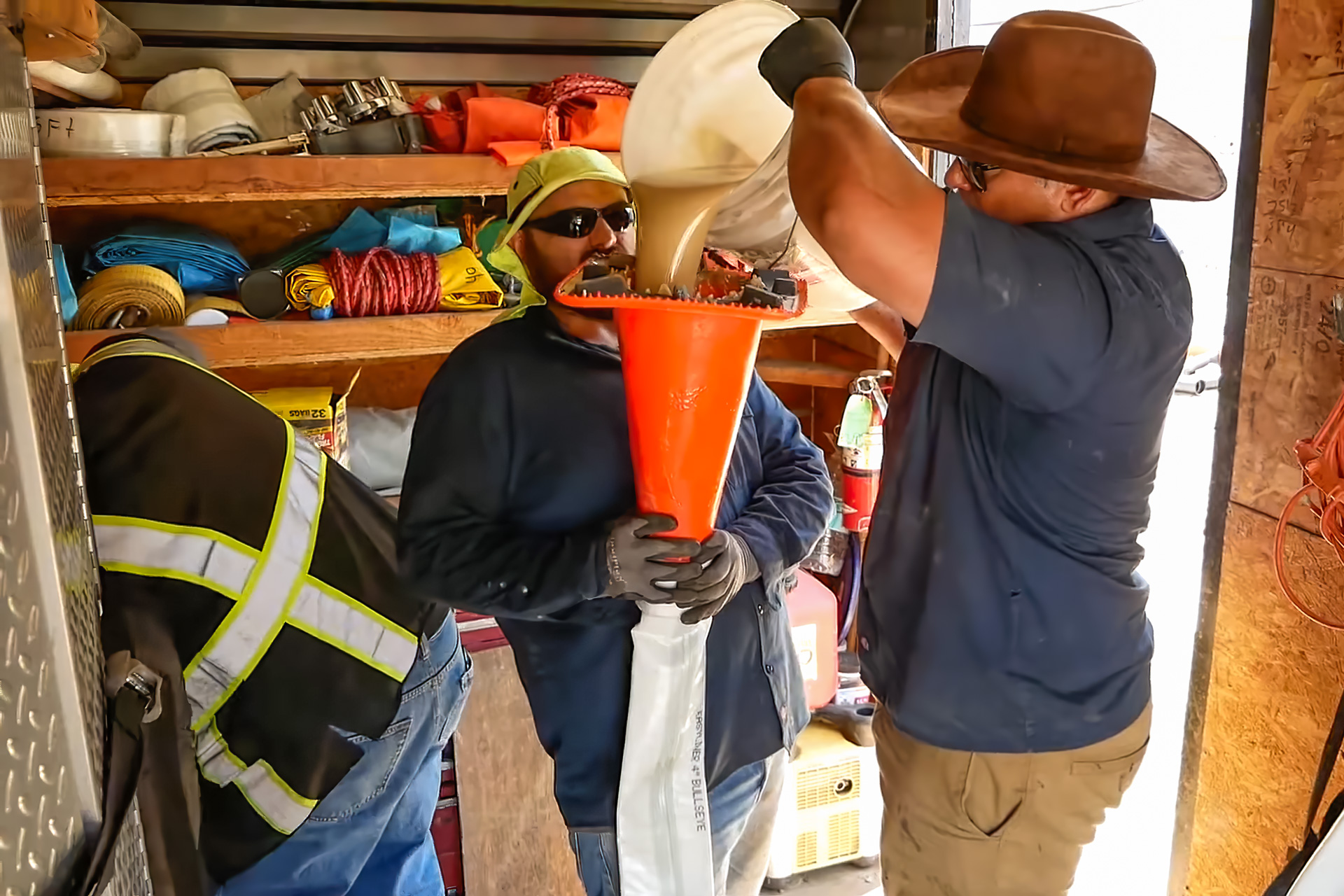

While one crew handled the pipe cleaning, another team prepared the epoxy liner by thoroughly impregnating it with resin.

Once the liner was ready, it was installed into the pipe using a delivery hose. Installation time ranged from 1 to 3 hours, depending on ambient temperature, weather conditions, and liner material.

Full curing and hardening of the liner took approximately 24 hours. After curing, the Almco Plumbing engineer performed a final video inspection to verify the results.

As part of the project, durable SDR-35 PVC pipes were used to fabricate service cleanouts. These were installed where the main line connects to the home’s internal drainage system. The restored pipe was pressure-tested and checked for flow efficiency throughout its length using a series of water discharge tests.

Once the plumbing work was complete, the trench was backfilled in layers, with each layer compacted using a power tamper to prevent future soil settling. This meticulous backfilling process ensured the lawn was left in pristine condition—virtually indistinguishable from its original state.

The entire project, from initial assessment to final cleanup, was completed in just one day.

Advantages of CIPP Inversion Technology for Residential Properties

CIPP inversion offers several key environmental and practical advantages, making it an ideal solution for residential sewer line restoration:

- Minimal Environmental Disruption. Since the process does not require extensive excavation or earthworks, it greatly reduces the impact on natural landscapes and surrounding ecosystems. For homeowners, this means significantly fewer disruptions during the repair process.

- Eco-Safe Epoxy Resins. The epoxy resins used in CIPP lining are environmentally safe and emit no harmful substances during installation. Once cured, the liner creates a sealed, leak-proof pipe that is safe for long-term use.

- Extended Pipe Lifespan. CIPP inversion extends the service life of existing pipeline systems by 50 years or more. This reduces the need for manufacturing and installing new pipes and helps minimize construction-related waste.

One of the major economic benefits of CIPP inversion is the reduction in overall project costs. Traditional sewer replacement methods involve not only digging and pipe replacement, but also the restoration of landscaping, driveways, or hardscapes—often accounting for a large portion of the total cost. With CIPP inversion, these expenses are drastically minimized thanks to its trenchless nature, and the work is typically completed in just one or two days.

In addition, this method reduces noise and air pollution, which is a significant advantage for both homeowners and their neighbors. Traditional methods that involve heavy construction equipment are often noisy and inconvenient, whereas CIPP inversion is virtually silent.

In this project, the use of CIPP inversion made it possible to restore the damaged sewer line and stop further wastewater leakage into the soil. All work—including trench digging, pipe cleaning, liner installation, final inspection, and site restoration—was completed in a single day, significantly reducing the inconvenience for the homeowner. New service cleanouts were also installed during the project, which will simplify future maintenance and inspection of the system.

In summary, CIPP inversion is a forward-looking solution for modern plumbing systems, especially when it comes to repairs or upgrades on residential properties. It represents a new standard in pipe restoration—combining innovation, long-term reliability, and environmental responsibility.