Professional Water Heater Installation in San Diego—Almco Plumbing Case Study

Proper water heater installation is key to ensuring the safe and efficient operation of the unit over time. Replacing outdated equipment with modern models can significantly reduce energy costs, which is especially important for owners of multi-unit buildings and apartment complexes. This case study outlines the replacement of a gas boiler for residential apartments in San Diego, with an emphasis on the technical aspects of the project.

Contents

Technologies & Services

Customer’s Problem—Brief Description

At the customer’s request, Almco Plumbing specialists replaced a boiler in an apartment complex in San Diego. The old unit had been in use for over 15 years and had become outdated, showing signs of wear—specifically, internal cracks had caused it to start leaking. Although commercial water heaters typically have a lifespan of around 10 years, this one had operated for 15.

Since the damage was beyond repair, the homeowner needed to replace the leaking water heater with a new, more efficient, and environmentally friendly model. As of 2024, new heaters in California must comply with current environmental standards and have low CO2 emissions. By upgrading to an eco-friendlier model, homeowners may be eligible for a rebate through SDG&E’s “Call Rebate Program”.

The following section describes the full installation and safe connection process in accordance with safety standards for such equipment.

Dismantling the Old Boiler

Prior to beginning the dismantling process, it was necessary to shut off the gas and water supplies—a critical safety measure. All water was drained from the plumbing system and the water heater tank. Supply lines were disconnected.

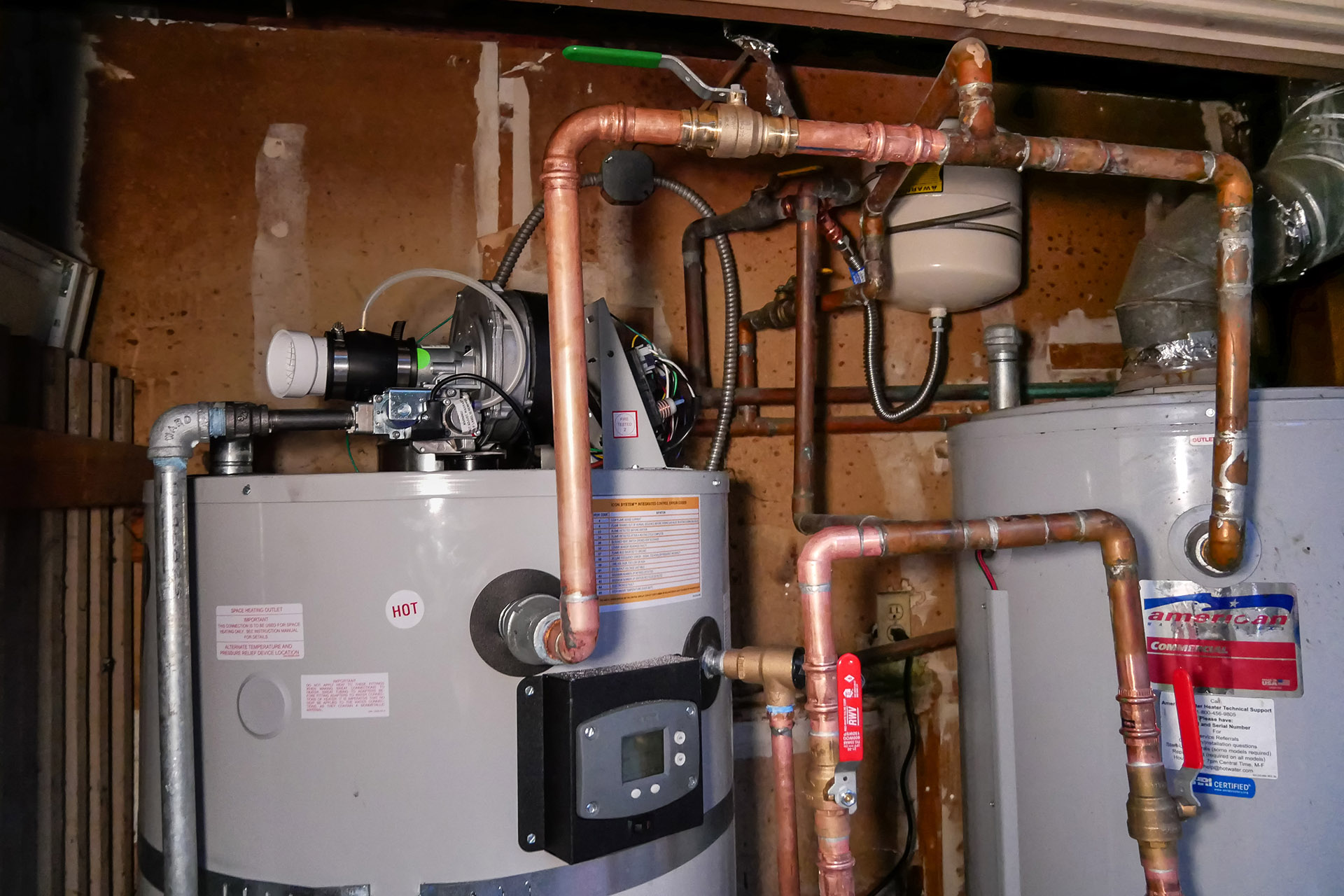

Some pipes were cut using a bandsaw, while others were unscrewed at the tank connection points. The pipes were made of copper, chosen for its corrosion resistance and long service life. Since the tank is quite heavy even when empty, a team of five people was required to remove it from the installation site. The dismantled unit was then taken for recycling and material recovery.

Installing the New Water Heater

Choosing a modern boiler not only reduces energy consumption but also cuts down CO2 emissions. These newer models regulate gas consumption and heat exchange efficiency, reducing fuel usage required to heat water.

- The Almco team prepped the installation area by removing old gas hoses, leveling the concrete base, and cleaning pipe ends of oxidation for a clean, secure connection to the plumbing system.

- All pipe ends were inspected for damage and any deformed sections were replaced with new copper pipes. Soldered joints were made using tin solder and a handheld gas torch to prepare for the installation of shut-off ball valves on both the supply and return lines.

- The new professional-grade water boiler was installed in the designated location and anchored to the concrete floor. Shut-off ball valves were attached to the copper water lines using crimp fittings and ProPress tools—ensuring durable, high-quality connections.

- A drain pipe with a shut-off valve was connected to the tank for easy future maintenance. A new copper recirculation pipe and an air release hose were also installed to prevent airlocks and ensure balanced hot water delivery throughout the building.

- A gas line was connected to the threaded fitting (detailed in the Efficient Gas Line Installation case). All threaded connections were sealed with polyester sealant for long-lasting durability.

- Gas line safety is paramount. A new galvanized steel vent pipe was added for safety and proper exhaust ventilation. This prevents combustion gases from entering living spaces, protecting indoor air quality. The vent installation followed fire safety codes and gas equipment regulations.

- The final step was system testing, conducted by an Almco Plumbing engineer to ensure full functionality and safety.